1. Selection of raw material conveyor

In the connection between the mixing process of the culture medium and the lifting and distribution process, the conveying methods are divided into: belt type, scraper type, and spiral type.

1. Belt conveyor

Advantages: simple structure, low cost, relatively clean surface, no friction between particles during transportation, and good heat dissipation of wet materials. Disadvantages: The belt surface will leak material, the service life is relatively short (belt hardening), and the belt hardening will slip when the temperature is too low in winter in the north. (Conveying angle is not more than 30┬░)

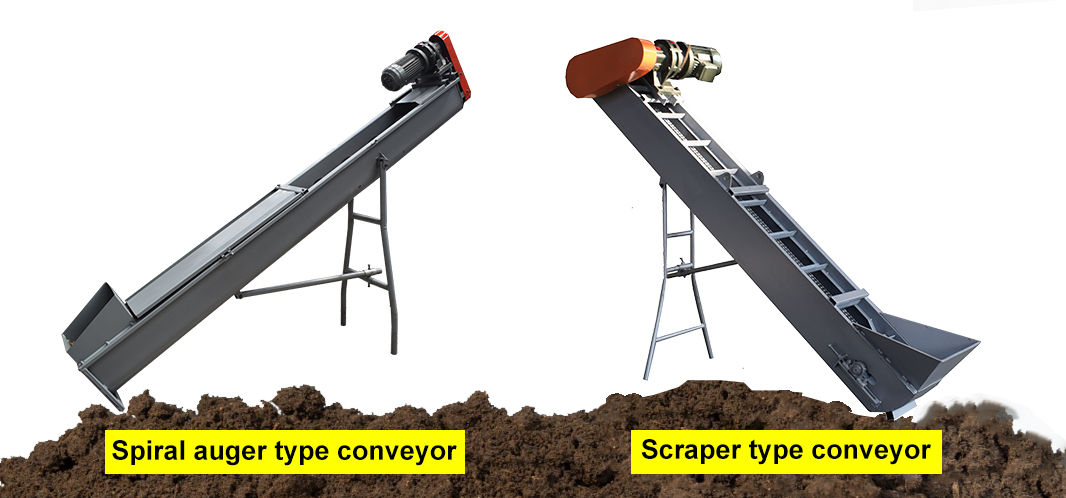

2. Scraper conveyor

Advantages: simple structure, easy maintenance, no leakage problem, and large conveying angle. Disadvantages: high noise, the chain becomes loose after a period of use and needs to be adjusted (the conveying angle is not more than 50┬░

3. Screw conveyor

Advantages: low noise, no culture medium remains in the conveyor, and high stability. Disadvantages: small conveying angle, high cost (the conveying angle is not more than 30┬░)

4. Upper conveyor

Choose according to the station of the bagging machine. If there are only 1~2 bagging machines, a distributing mixer can be used with a conveyor to feed the bagging; if there are more than 2 bagging machines, it is more convenient to use an upper conveyor for feeding.