1. Place the mushrooms in the autoclave at the specified quantity and density. If the quantity and density are too high, steam penetration will be affected, and the sterilization time will be extended.

2. If the culture medium formula changes, the gaps between the substrates may become smaller or larger, and the sterilization procedure must be modified accordingly. Failure to do so may result in contamination or energy waste.

3. Confirm that the autoclave's exhaust delay control selector switch is in the "off" position.

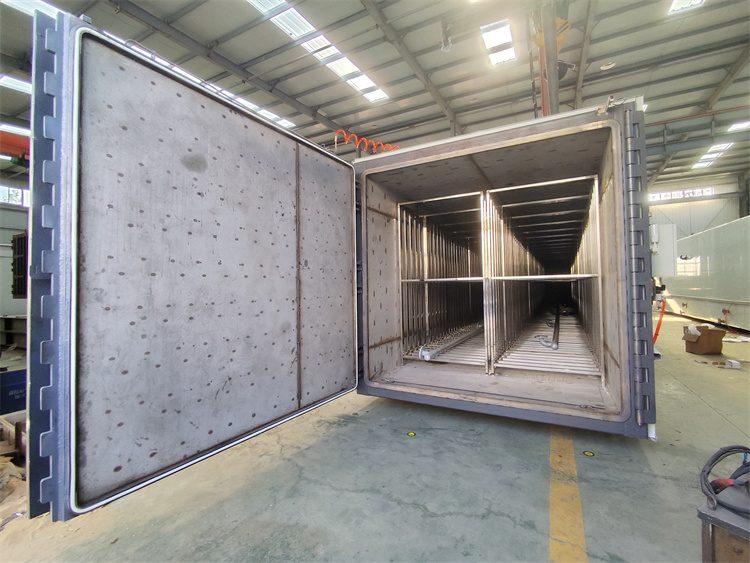

4. Confirm that the autoclave door is properly sealed.

5. Clean the joints of the autoclave door and close it.

6. Before automatically running the sterilization process, confirm the accuracy of the setpoints.

7. Pay attention to changes in the sound of incoming steam. Report any abnormalities immediately to the equipment department for repair.

8. Because the exhaust valve is at high temperature, exercise caution when opening and closing it to prevent burns.

9. Fully automatic autoclaves use a degassing process after sterilization to equalize the pressure inside and outside the autoclave, making it easier to open the door. An air filter should be installed to allow outside air to flow back into the autoclave through the filter to avoid affecting the sterilization effect.

4. Ten Safety Precautions for the Sterilization Process

ŌæĀ Operators must wear protective equipment, such as rubber gloves, before starting work.

ŌæĪ Operators must work in pairs when entering and exiting the sterilizer to prevent accidents.

Ōæó Clean the area around the equipment and do not store any items unrelated to the work.

ŌæŻ Ensure that the equipment's control switches, safety devices, and emergency stop switches are not damaged or malfunctioning. Report any abnormalities to your supervisor immediately.

Ōæż Maintain focus during work and avoid unrelated activities. Ōæź Check the main valve pressure when starting the machine and the safety valve once a week. During machine operation, strictly follow the operating procedures and accurately record relevant parameters such as the sterilization time. Ōæ” Never turn on the power switch with wet hands to avoid electric shock.

@ When cleaning or maintaining the equipment, the machine must be shut down, the power supply disconnected, and a "Equipment Under Maintenance, Do Not Turn On" sign displayed before proceeding. Ōæ© During the sterilization process, it is strictly forbidden to leave your post without permission. Observe the equipment's operation throughout the process and promptly report any emergency issues such as leaks to the relevant authorities.

After the sterilization process is complete, promptly turn off the power, clean the equipment, and keep the work area clean and tidy.