Most factories use liquid spawns for efficient, industrialized, and standardized cultivation, addressing intensive production bottlenecks.

1. Types and Selection of Shakers

- Reciprocating shakers: 80-140 r/min frequency, 5-14 cm stroke; lower cost, suitable for small factories; risk of liquid splashing and contamination if parameters are improper. - Rotary shakers: 3-6 cm eccentricity, 60-300 r/min speed; complex structure, higher cost, better oxygen transfer, lower power consumption, no liquid splashing; used in large factories/laboratories.

2. Shake Flask Culture Process Flow

Prepare medium ŌåÆ Package ŌåÆ Sterilize ŌåÆ Cool ŌåÆ Inoculate ŌåÆ Shake flask culture.

3. Key Points for Shake Flask Production

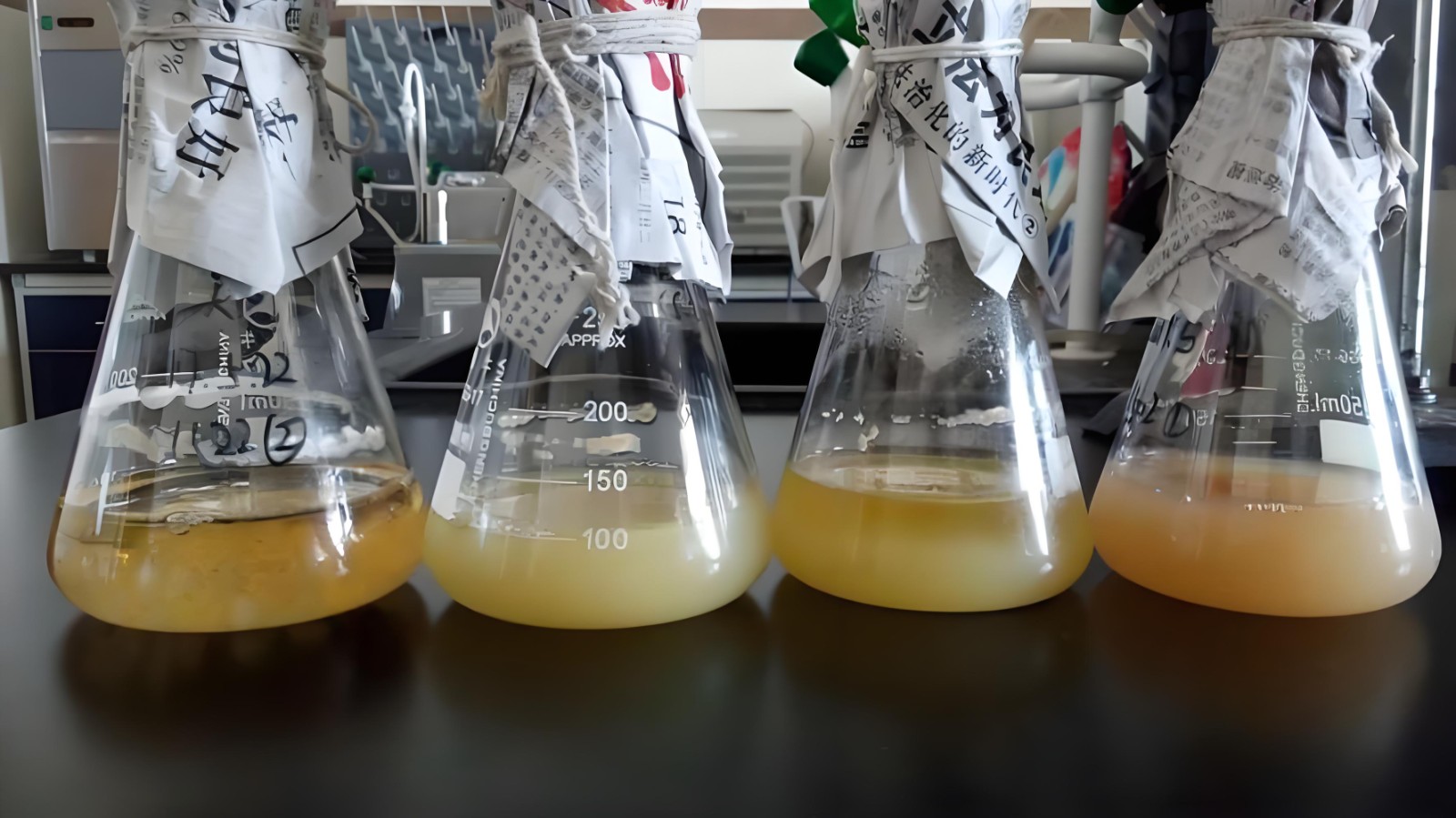

- Medium formula: 200g potatoes, 20g glucose, 5g peptone, 2.0g KHŌééPOŌéä, 1.0g MgSOŌéä, vitamin B1, pH 6.8-7.0, 1000ml water. - Medium preparation: Boil potatoes, filter, add ingredients (peptone dissolved in cold water first), adjust pH (slightly higher before sterilization as it drops after autoclaving). - Packaging: Pour into Erlenmeyer flasks (50ml in 250-300ml flasks; 150ml in 500ml flasks) with 10 glass beads; seal with silicone breathable stoppers (or 12-layer gauze + kraft paper/newspaper). - Sterilization and cooling: Autoclave at 121┬░C for 30 minutes; cool to below 30┬░C, place in clean bench. - Inoculation: Use fresh slant cultures; inoculate 2-3 cm┬▓ mycelia per flask under sterile conditions; 4-5 flasks per slant; label. - Cultivation: Static incubation at 25┬░C for 48h, then shake culture (100 rpm for reciprocating, 150 rpm for rotary shakers) at 25┬░C for 5-7 days. Qualified when: no contamination, hyphae dry weight 1.5g/100ml, mycelial pellets 1-2mm in diameter; use immediately to avoid aging. - Storage: Store at 4┬░C. - Quality requirements: Clear medium, dense brown mycelial pellets (like millet porridge), no impurities/autolysis/wall detachment, sweet smell; no foreign bacteria under microscopy.